Why is reverse logistics management important in ecommerce?

Apr 12, 2024

4 min

read

Last updated:

Oct 31, 2024

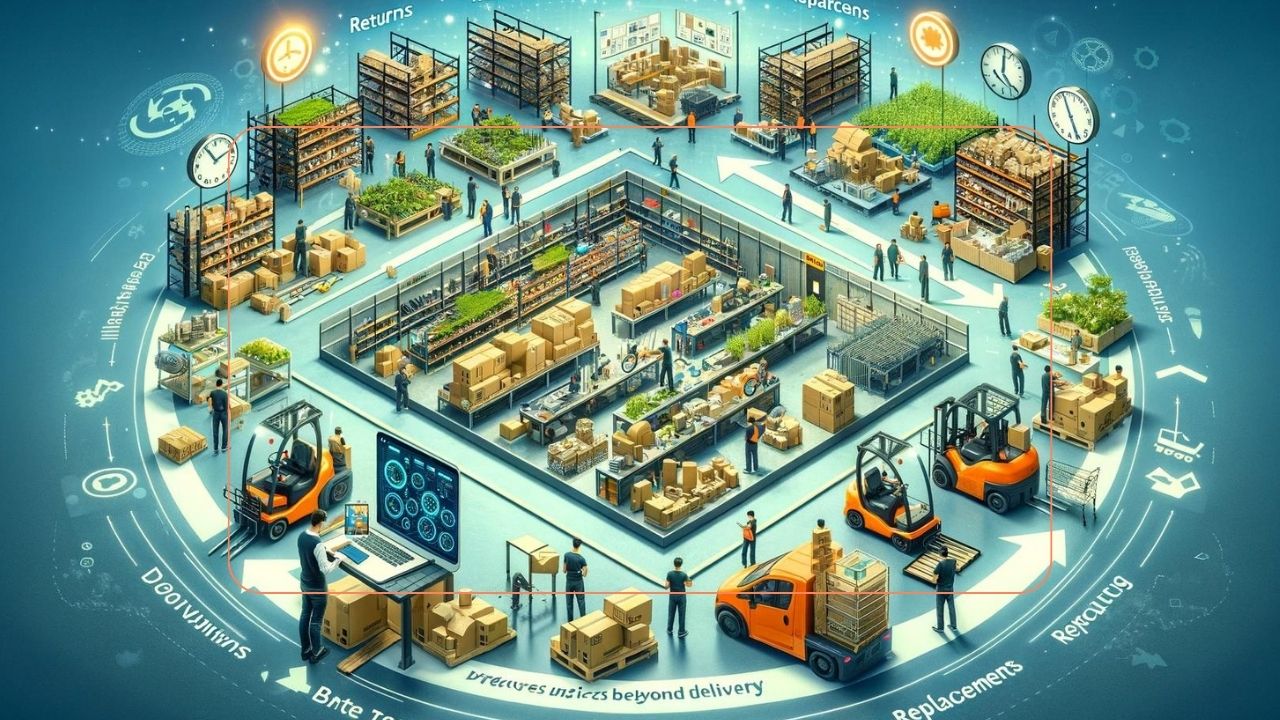

Reverse logistics can be cost-effective to your business and improve the customer experience. However, if returns, replacements and recycling are a core part of your product offering, it’s important to get it right. With this in mind, we’re exploring reverse logistics management and why it’s so important in ecommerce. In this guide, we’ll cover:

Where does reverse logistics fit into the ecommerce supply chain?

The 5 ‘Rs’ of reverse logistics: returns, reselling, repairs, replacements and recycling.

What are the biggest challenges when it comes to reverse logistics for ecommerce businesses?

Coordinating reverse logistics for ecommerce businesses.

Where does reverse logistics fit into the ecommerce supply chain?

Reverse logistics occurs after a parcel has been delivered to a customer. It involves the customer sending goods back to the retailer or manufacturer. This could be because they’re dissatisfied with the product, a product is unsuitable, it needs to be repaired, they need a replacement, or the product needs recycling. Once a product has been returned, it will then be checked at the warehouse facility and, if required, a refund will be processed.

The 5 ‘Rs’ of reverse logistics: returns, reselling, repairs, replacements and recycling.

There are different types of reverse logistics. These are known as the 5 ‘Rs’ and include returns, reselling, repairs, replacement and recycling. But what does each type of reverse logistics involve?

Returns.

Sometimes the product you’re selling just doesn’t meet a customer’s expectations. They may have ordered the wrong size or multiple sizes, or upon receiving the product they decided they no longer want or need it. This triggers a return. Customer returns should align with your returns policy and strike a balance between customer satisfaction and encouraging future purchases.

Reselling.

Some returned items can be resold if they’re in good condition. Many items are returned due to customer preference rather than faulty products. Reselling prevents these products being sent to landfill.

Returned products are inspected when they arrive back at your warehouse to assess the quality. Then, they are retagged, added back into the system, re-listed and repackaged ready for sale again. Reselling can make your business more sustainable while reducing costs and adding to your bottom line.

Repairs.

Customers may return a recently purchased item that’s faulty, or send in an older product to be repaired. Rather than sending faulty items to landfill, they can often be repaired and resold. These products are often listed as “reconditioned”, or even discounted because of defects.

Replacements.

There are many reasons why a customer may want to replace a product. They may want a different colour or size, or may wish to replace a faulty item. If this is the case, the chances are they already like your product and brand, so you should make this process as smooth as possible.

Recycling.

With many businesses and customers trying to make more sustainable choices, recycling initiatives are becoming increasingly popular. This could be the recycling of old products through the original manufacturer, a third party, or by donating to a charity.

Offering a recycling service is simple to implement with the right reverse logistics software.

What are the biggest challenges when it comes to reverse logistics for ecommerce businesses?

Ecommerce reverse logistics can often be challenging for businesses because they rely on customer returns to come back to their business, without a lot of control. Some of the common reverse logistics problems in ecommerce include:

High return rates.

Complex returns processes.

Inefficient management software.

High carriage costs.

Data capture and analysis.

High return rates.

Managing a high volume of returns can be a challenge, whether it’s returned products or goods for recycling or donation purposes. So, using the right software to streamline the process can make returns easier to manage.

Complex returns processes.

Complex return processes can reduce the number of return customers if the process is lengthy and difficult. This can reduce the number of repeat orders in the future if the returns process is difficult.

Inefficient management software.

Poor management software can make it difficult from a warehouse and ecommerce point of view, especially if you’re not storing information correctly about what’s in stock, or what products have been returned.

High carriage costs.

Weight and size limits can often lead to high carriage costs. However, you can make your carriage costs more efficient by minimising packaging and reducing wasted space.

Data capture and analysis.

It’s important to capture customised data about your customers and the reasons for their returns. By learning this information, you can work towards reducing returns in the future.

Share article.

News & Updates

Get specially curated goodness delivered straight to your inbox.

Last updated:

Oct 31, 2024

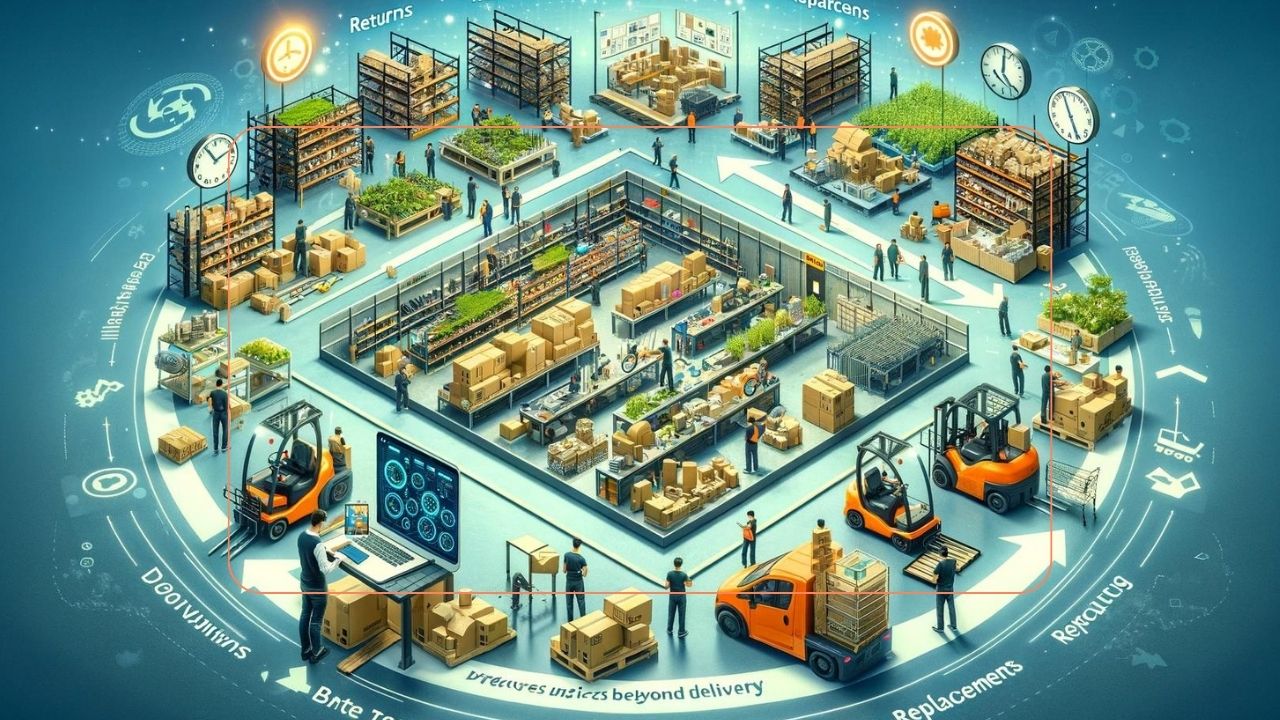

Reverse logistics can be cost-effective to your business and improve the customer experience. However, if returns, replacements and recycling are a core part of your product offering, it’s important to get it right. With this in mind, we’re exploring reverse logistics management and why it’s so important in ecommerce. In this guide, we’ll cover:

Where does reverse logistics fit into the ecommerce supply chain?

The 5 ‘Rs’ of reverse logistics: returns, reselling, repairs, replacements and recycling.

What are the biggest challenges when it comes to reverse logistics for ecommerce businesses?

Coordinating reverse logistics for ecommerce businesses.

Where does reverse logistics fit into the ecommerce supply chain?

Reverse logistics occurs after a parcel has been delivered to a customer. It involves the customer sending goods back to the retailer or manufacturer. This could be because they’re dissatisfied with the product, a product is unsuitable, it needs to be repaired, they need a replacement, or the product needs recycling. Once a product has been returned, it will then be checked at the warehouse facility and, if required, a refund will be processed.

The 5 ‘Rs’ of reverse logistics: returns, reselling, repairs, replacements and recycling.

There are different types of reverse logistics. These are known as the 5 ‘Rs’ and include returns, reselling, repairs, replacement and recycling. But what does each type of reverse logistics involve?

Returns.

Sometimes the product you’re selling just doesn’t meet a customer’s expectations. They may have ordered the wrong size or multiple sizes, or upon receiving the product they decided they no longer want or need it. This triggers a return. Customer returns should align with your returns policy and strike a balance between customer satisfaction and encouraging future purchases.

Reselling.

Some returned items can be resold if they’re in good condition. Many items are returned due to customer preference rather than faulty products. Reselling prevents these products being sent to landfill.

Returned products are inspected when they arrive back at your warehouse to assess the quality. Then, they are retagged, added back into the system, re-listed and repackaged ready for sale again. Reselling can make your business more sustainable while reducing costs and adding to your bottom line.

Repairs.

Customers may return a recently purchased item that’s faulty, or send in an older product to be repaired. Rather than sending faulty items to landfill, they can often be repaired and resold. These products are often listed as “reconditioned”, or even discounted because of defects.

Replacements.

There are many reasons why a customer may want to replace a product. They may want a different colour or size, or may wish to replace a faulty item. If this is the case, the chances are they already like your product and brand, so you should make this process as smooth as possible.

Recycling.

With many businesses and customers trying to make more sustainable choices, recycling initiatives are becoming increasingly popular. This could be the recycling of old products through the original manufacturer, a third party, or by donating to a charity.

Offering a recycling service is simple to implement with the right reverse logistics software.

What are the biggest challenges when it comes to reverse logistics for ecommerce businesses?

Ecommerce reverse logistics can often be challenging for businesses because they rely on customer returns to come back to their business, without a lot of control. Some of the common reverse logistics problems in ecommerce include:

High return rates.

Complex returns processes.

Inefficient management software.

High carriage costs.

Data capture and analysis.

High return rates.

Managing a high volume of returns can be a challenge, whether it’s returned products or goods for recycling or donation purposes. So, using the right software to streamline the process can make returns easier to manage.

Complex returns processes.

Complex return processes can reduce the number of return customers if the process is lengthy and difficult. This can reduce the number of repeat orders in the future if the returns process is difficult.

Inefficient management software.

Poor management software can make it difficult from a warehouse and ecommerce point of view, especially if you’re not storing information correctly about what’s in stock, or what products have been returned.

High carriage costs.

Weight and size limits can often lead to high carriage costs. However, you can make your carriage costs more efficient by minimising packaging and reducing wasted space.

Data capture and analysis.

It’s important to capture customised data about your customers and the reasons for their returns. By learning this information, you can work towards reducing returns in the future.

Share article.

News & Updates

Get specially curated goodness delivered straight to your inbox.

Last updated:

Oct 31, 2024

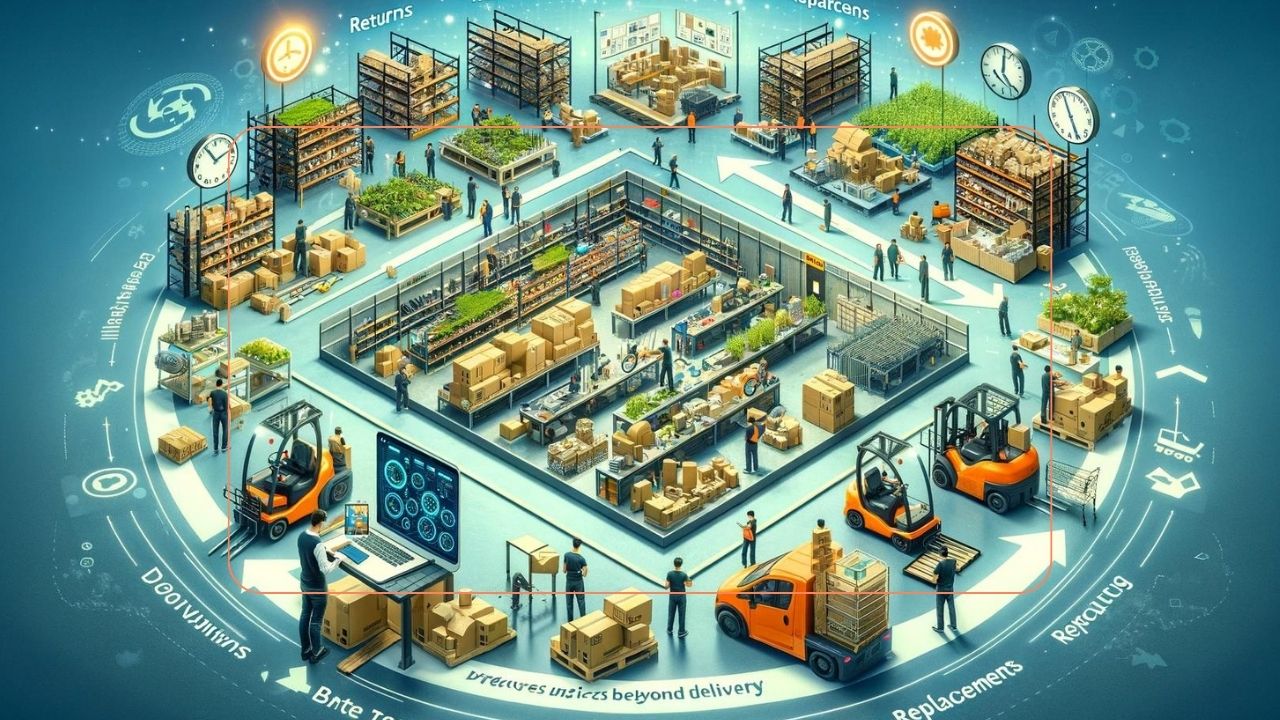

Reverse logistics can be cost-effective to your business and improve the customer experience. However, if returns, replacements and recycling are a core part of your product offering, it’s important to get it right. With this in mind, we’re exploring reverse logistics management and why it’s so important in ecommerce. In this guide, we’ll cover:

Where does reverse logistics fit into the ecommerce supply chain?

The 5 ‘Rs’ of reverse logistics: returns, reselling, repairs, replacements and recycling.

What are the biggest challenges when it comes to reverse logistics for ecommerce businesses?

Coordinating reverse logistics for ecommerce businesses.

Where does reverse logistics fit into the ecommerce supply chain?

Reverse logistics occurs after a parcel has been delivered to a customer. It involves the customer sending goods back to the retailer or manufacturer. This could be because they’re dissatisfied with the product, a product is unsuitable, it needs to be repaired, they need a replacement, or the product needs recycling. Once a product has been returned, it will then be checked at the warehouse facility and, if required, a refund will be processed.

The 5 ‘Rs’ of reverse logistics: returns, reselling, repairs, replacements and recycling.

There are different types of reverse logistics. These are known as the 5 ‘Rs’ and include returns, reselling, repairs, replacement and recycling. But what does each type of reverse logistics involve?

Returns.

Sometimes the product you’re selling just doesn’t meet a customer’s expectations. They may have ordered the wrong size or multiple sizes, or upon receiving the product they decided they no longer want or need it. This triggers a return. Customer returns should align with your returns policy and strike a balance between customer satisfaction and encouraging future purchases.

Reselling.

Some returned items can be resold if they’re in good condition. Many items are returned due to customer preference rather than faulty products. Reselling prevents these products being sent to landfill.

Returned products are inspected when they arrive back at your warehouse to assess the quality. Then, they are retagged, added back into the system, re-listed and repackaged ready for sale again. Reselling can make your business more sustainable while reducing costs and adding to your bottom line.

Repairs.

Customers may return a recently purchased item that’s faulty, or send in an older product to be repaired. Rather than sending faulty items to landfill, they can often be repaired and resold. These products are often listed as “reconditioned”, or even discounted because of defects.

Replacements.

There are many reasons why a customer may want to replace a product. They may want a different colour or size, or may wish to replace a faulty item. If this is the case, the chances are they already like your product and brand, so you should make this process as smooth as possible.

Recycling.

With many businesses and customers trying to make more sustainable choices, recycling initiatives are becoming increasingly popular. This could be the recycling of old products through the original manufacturer, a third party, or by donating to a charity.

Offering a recycling service is simple to implement with the right reverse logistics software.

What are the biggest challenges when it comes to reverse logistics for ecommerce businesses?

Ecommerce reverse logistics can often be challenging for businesses because they rely on customer returns to come back to their business, without a lot of control. Some of the common reverse logistics problems in ecommerce include:

High return rates.

Complex returns processes.

Inefficient management software.

High carriage costs.

Data capture and analysis.

High return rates.

Managing a high volume of returns can be a challenge, whether it’s returned products or goods for recycling or donation purposes. So, using the right software to streamline the process can make returns easier to manage.

Complex returns processes.

Complex return processes can reduce the number of return customers if the process is lengthy and difficult. This can reduce the number of repeat orders in the future if the returns process is difficult.

Inefficient management software.

Poor management software can make it difficult from a warehouse and ecommerce point of view, especially if you’re not storing information correctly about what’s in stock, or what products have been returned.

High carriage costs.

Weight and size limits can often lead to high carriage costs. However, you can make your carriage costs more efficient by minimising packaging and reducing wasted space.

Data capture and analysis.

It’s important to capture customised data about your customers and the reasons for their returns. By learning this information, you can work towards reducing returns in the future.

Share article.

News & Updates

Get specially curated goodness delivered straight to your inbox.